Surface Squeezing

A compression Test was a also performed in a separate group of samples which were cut with the measurements outlined in ASTM D695. This test is done simply to observe the failure modes and how the objects react under compression. This may be important to analyze if permanent deformation could occur when a load is subjected at the outer edges of the manhole cover. Testing was done with MTS TestWorks 4 using a compression test setting under 5 mm per minute until failure occurred in the specimen. The purpose of the test is to derive the compressive strength, and modulus of elasticity of the specimens.

An average of 4 samples were tested for each type of sample.The strain of the samples were recorded until failure occurred. The maximum load is also also recorded when the specimen fails. Standard deviation is taken into account when analyzing the data for the mechanical properties of the material.

Equations

Results

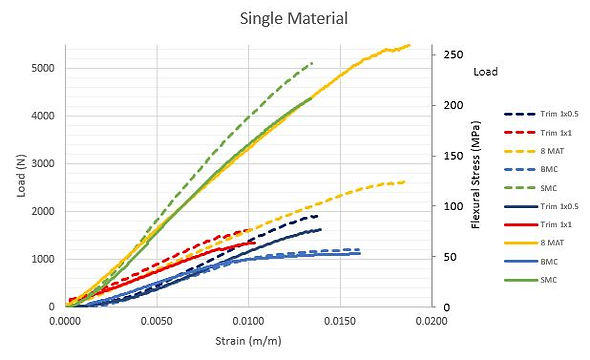

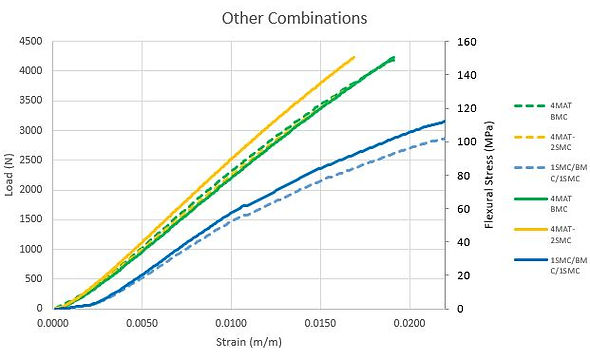

About six of each material was tested for the compression test. The failure of the compression molding samples seems to be the results of the material buckling or kinking. Like the Flexural testing, load displacement curves were made for the testing results and the elastic modulus was derived from these values. The values of the load displacement curve sharply drops when the material fails.

The average failure load was about 17.13 to 32.4 kN, with deviations ranging from 0.82 to 8.81 kN. The Mat and SMC resulted in the highest compression strength, while the 1" x 1" Trim sample resulted in the lowest. The results for the elastic modulus reflects the results of the compression strength; the Mat had the highest while the trim had the lowest results.

Compression Test Failure